Turning

trash into

cash

With half the world’s used tyres stockpiled annually, valorisation through recycling remains marginal, limited by a lack of eco-viable and economically lucrative solutions - until now.

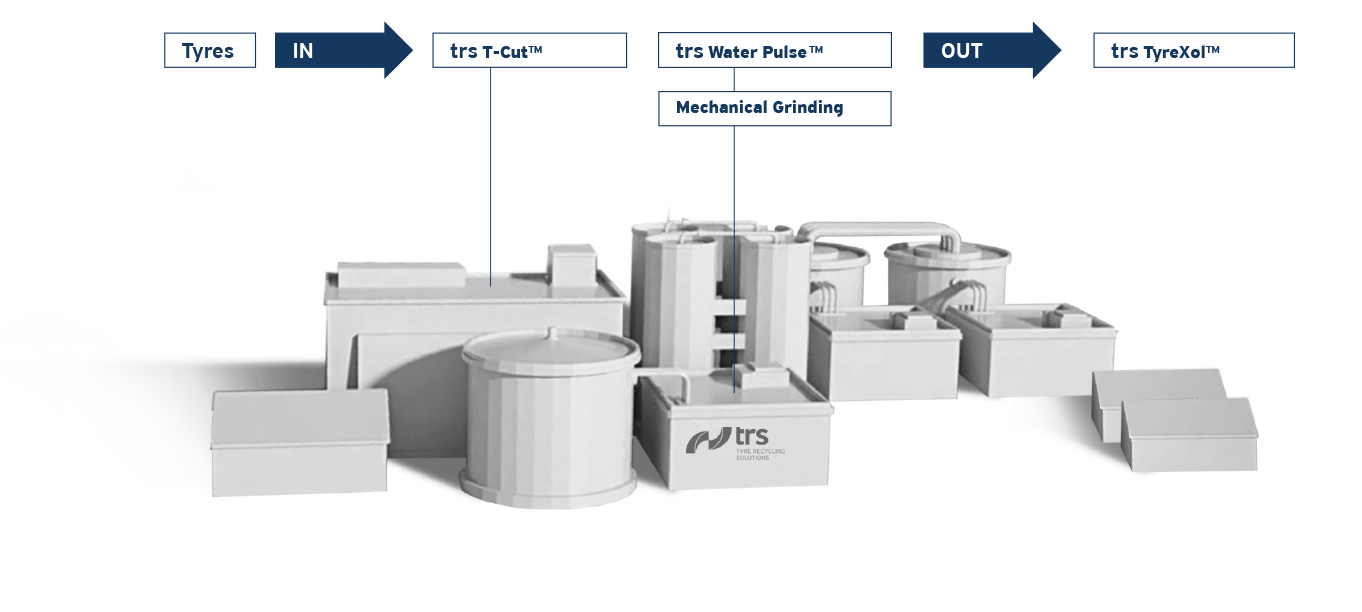

A proprietary tyre cutting process splits tyres into 3 flat parts, optimizing storage and logistics up to 50%, and is the prime first step to total recycling.

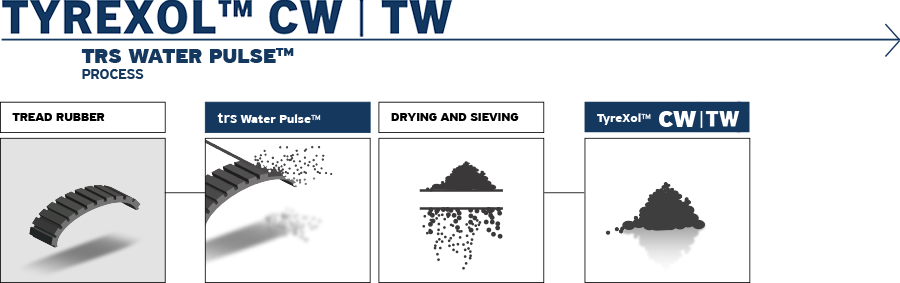

A proprietary and highly specialized water-jet system pulverizes tyre tread into fine powder, free from steel and synthetic fibres. Heat- and chemical-free jet milling ensures highest quality powder outputs between 0 and 1mm.

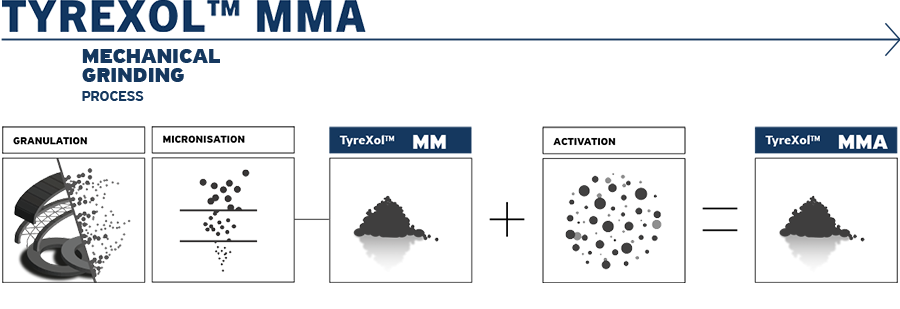

Ambient grinding of tyre sidewalls and carcass designed for high quality standard TyreXolTM powder.

As a Recycling Partner producing TyreXol™, you enter a prime circular value chain supported by our comprehensive lineup of proprietary solutions turning your stockpiles into profits.

TRS ‘solutions can be part of a greenfield project or be added to an existing tyre recycling facility.